The alum tanning process did not successfully tan the first test strip. The test strip remained cream colored and rubbery. It was unclear whether the alum tanning process did not work or if the test strip was not properly bated. The third test strip will be used to determine which process did not work.

Vegetable Tanning

The second test strip was left in the vegetable tanning solution. This piece has become deeper in color.

Dehairing

Hair was removed from the 3rd test strip.

Soaking

The third test strip was soaked in distilled water to remove the sodium hydroxide.Baiting

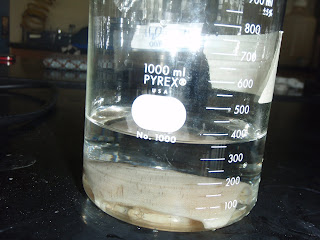

6 g of pepsin were added to 600 mL of distilled water and 18 mL of acetic acid. This solution was heated to 37°C. The third test strip was placed in this solution and the hot plate's magnetic stirrer was used to stirr the solution.